Industry 4.0: The importance of getting more efficiency out of the manufacturing process

The Annual Manufacturing Report (AMR) 2018, published by Hennik Research and produced by The Manufacturer and supported and sponsored by lots of top industry names. Discusses the need to future-proof your business, in-order to evolve fast enough for the end consumer.

/ 3

The Annual Manufacturing Report (AMR) 2018, published by Hennik Research and produced by The Manufacturer and supported and sponsored by lots of top industry names. Discusses the need to future-proof your business, in-order to evolve fast enough for the end consumer.

From a hydraulics perspective, it’s interesting reading about Industry 4.0 and the opportunity we must take to advance. However, I can see how it can be quite a daunting prospect and it is a long road yet.

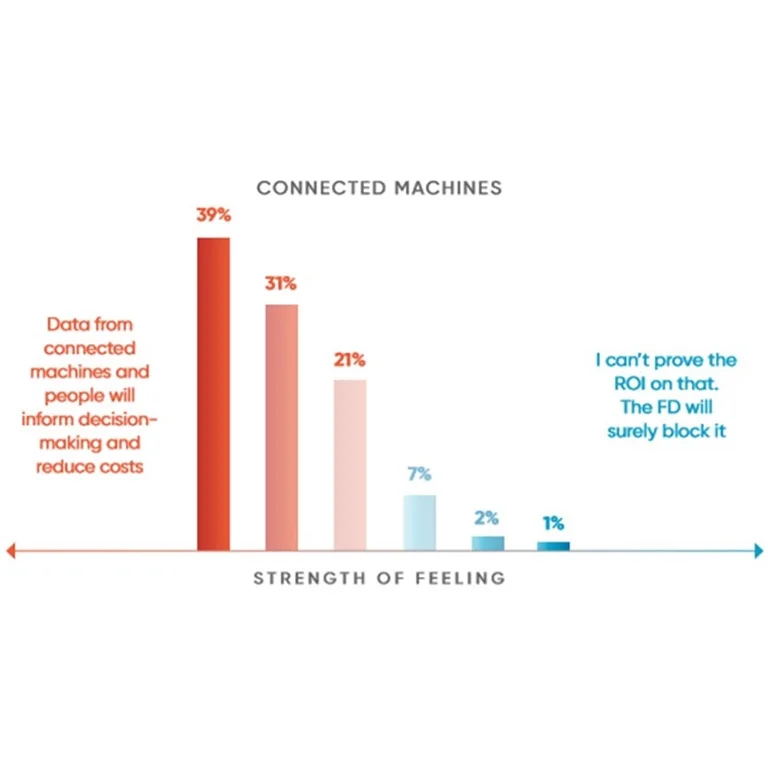

The impact of Industry 4.0 on our manufacturing processes has potential to be great. Of those surveyed for the AMR, 39% are getting connected machines, or were planning to 31%. On the other end of the scale those that were not at all interested were in the minority (1%) or maybe they just weren’t ready to make that step yet (2%). Making a move towards Industry 4.0 and getting connected machines with live data allows decision makers to see weaknesses in the process before they occur and therefore adjust for greater efficiency. The AMR states a clear 91% of respondents understand this.

Extract above from AMR – on adoption of smart factories.

For Industry 4.0 to be a success in UK manufacturing and to bring with it reliability and continuous productivity, operational improvements need to be made.

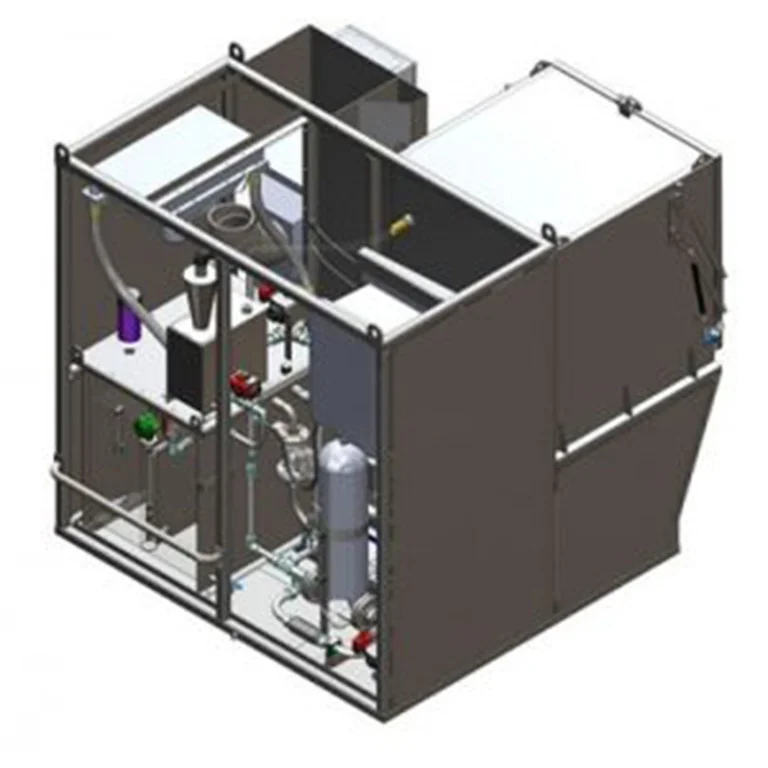

One significant area where we can help UK manufacturers is by the supply of bespoke Test Rigs. Test Rigs are a facility used to test industrial components and they can satisfy the need for live performance data.

Usually our customers requirements for a test rig can differ greatly but the aim, is to test a component against a certain measure, such as; pressure testing, fatigue testing or brake testing etc.

We have many examples of the test rigs which we have produced, they are all unique to each customers design specification, stretching across several areas of industry; industrial, aerospace, automotive, construction, oil and gas and energy production